Marka la barbardhigo matoorrada qulqulka radial, matoorrada qulqulka axial waxay leeyihiin faa'iidooyin badan oo ku saabsan naqshadeynta gawaarida korontada ku shaqeeya. Tusaale ahaan, matoorrada qulqulka axial waxay beddeli karaan naqshadeynta tareenka korontada ku shaqeeya iyagoo matoorka ka dhaqaajinaya axle una wareejinaya gudaha giraangiraha.

1. Xariiqda awoodda

Matoorada qulqulka axialwaxay helayaan dareen sii kordhaya (kor u qaadis). Sannado badan, noocan mootada waxaa loo isticmaali jiray codsiyada taagan sida wiishashka iyo mashiinnada beeraha, laakiin tobankii sano ee la soo dhaafay, horumariyayaal badan ayaa ka shaqeynayay sidii loo horumarin lahaa tiknoolajiyadan loona dabaqi lahaa mootooyinka korontada ku shaqeeya, kuraasta garoonka diyaaradaha, gawaarida xamuulka qaada, gawaarida korontada ku shaqeeya, iyo xitaa diyaaradaha.

Matoorada socodka radial-ka ee dhaqameed waxay isticmaalaan birlabyo joogto ah ama matoorro soo-saarid ah, kuwaas oo horumar la taaban karo ka sameeyay hagaajinta miisaanka iyo kharashka. Si kastaba ha ahaatee, waxay la kulmaan dhibaatooyin badan oo ku saabsan sii wadida horumarinta. Socodka axial-ka, oo ah nooc gebi ahaanba ka duwan matoorka, ayaa laga yaabaa inuu noqdo beddel wanaagsan.

Marka la barbardhigo matoorada radial-ka, aagga dusha sare ee birlabta ee wax ku oolka ah ee matoorada birlabta ee joogtada ah ee qulqulka axial waa dusha sare ee rotor-ka matoorka, ee maaha dhexroorka dibadda. Sidaa darteed, mugga matoorka, matoorada birlabta ee joogtada ah ee qulqulka axial waxay badanaa bixin karaan xoog weyn.

Matoorada qulqulka axialwaa kuwo aad u yar; Marka la barbardhigo matoorrada radial-ka, dhererka dhidibka matoorku aad ayuu uga gaaban yahay. Matoorrada giraangiraha gudaha, tani badanaa waa arrin muhiim ah. Qaab-dhismeedka is haysta ee matoorrada dhidibka wuxuu hubiyaa cufnaanta awoodda iyo cufnaanta awoodda oo ka sarreysa matoorrada radial-ka ee la midka ah, sidaas darteedna wuxuu meesha ka saarayaa baahida loo qabo xawaaraha hawlgalka oo aad u sarreeya.

Waxtarka matoorrada qulqulka axial sidoo kale aad ayuu u sarreeyaa, badanaa wuxuu ka badan yahay 96%. Tani waxay ugu wacan tahay wadada socodka gaaban, hal cabbir, taas oo la barbar dhigi karo ama xitaa ka sarreysa hufnaanta marka la barbar dhigo matoorrada qulqulka radial 2D ee ugu fiican suuqa.

Dhererka matoorku waa gaaban yahay, badanaa 5 ilaa 8 jeer ayuu ka gaaban yahay, miisaankana sidoo kale waxaa hoos u dhacaya 2 ilaa 5 jeer. Labadan arrimood ayaa beddelay doorashada naqshadeeyayaasha goobaha baabuurta korontada ku shaqeeya.

2. Tiknoolajiyada qulqulka axial

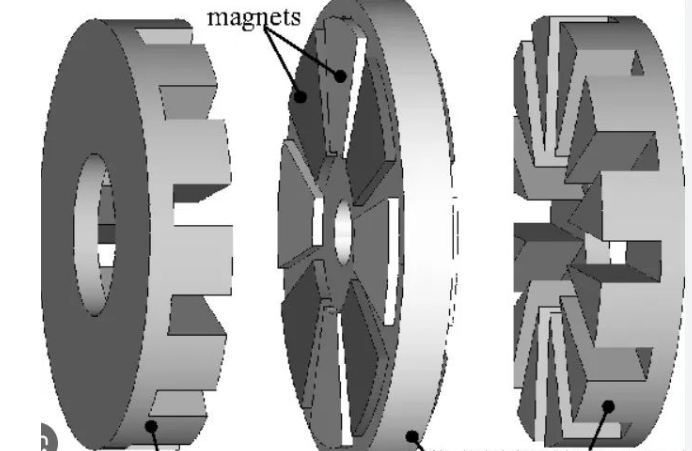

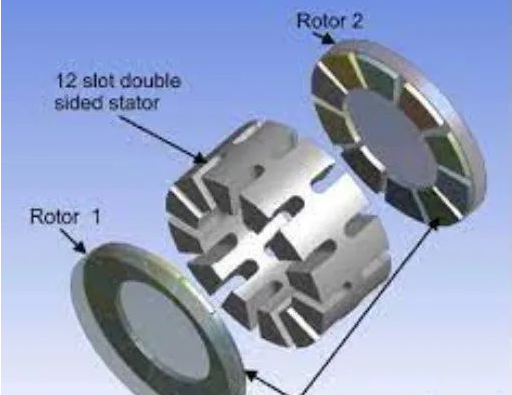

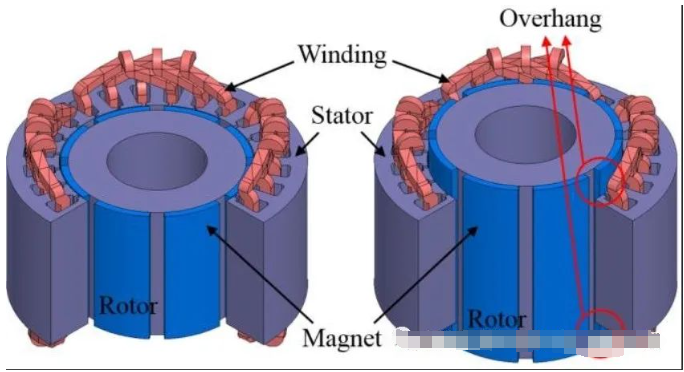

Waxaa jira laba topology oo ugu muhiimsan ee loo isticmaalo daaweyntamatoorada qulqulka axial: laba-rotor hal stator ah (mararka qaarkood waxaa loo yaqaan mashiinnada qaabka torus) iyo hal rotor laba stator ah.

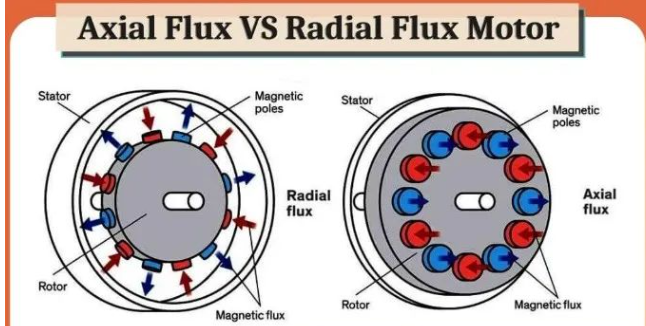

Waqtigan xaadirka ah, inta badan matoorada magnet-ka joogtada ah waxay isticmaalaan topology-ga qulqulka radial. Wareegga qulqulka magnetic-ga wuxuu ka bilaabmaa magnet joogto ah oo ku yaal rotor-ka, wuxuu dhex maraa iliga koowaad ee stator-ka, ka dibna si radial ah ayuu ugu socdaa stator-ka. Kadib wuxuu dhex maraa iliga labaad si uu u gaaro birta magnetic-ga labaad ee rotor-ka. Qaab-dhismeedka qulqulka dhidibka rotor-ka ee laba-geesoodka ah, wareegga qulqulka wuxuu ka bilaabmaa magnet-ka koowaad, wuxuu si dhidib ah uga gudbaa ilkaha stator-ka, isla markiiba wuxuu gaaraa magnet-ka labaad.

Taas macnaheedu waa in wadada qulqulka ay aad uga gaaban tahay tan matoorada qulqulka radial, taasoo keentay mugga matoorka oo yar, cufnaanta awoodda oo sareysa iyo hufnaanta isla awoodda.

Matoor radial ah, halkaas oo qulqulka birlabta uu ka gudbo iliga koowaad ka dibna uu ku laabto iliga xiga isagoo maraya stator-ka, isagoo gaaraya birlabta. Dareeraha birlabta wuxuu raacaa waddo laba-geesood ah.

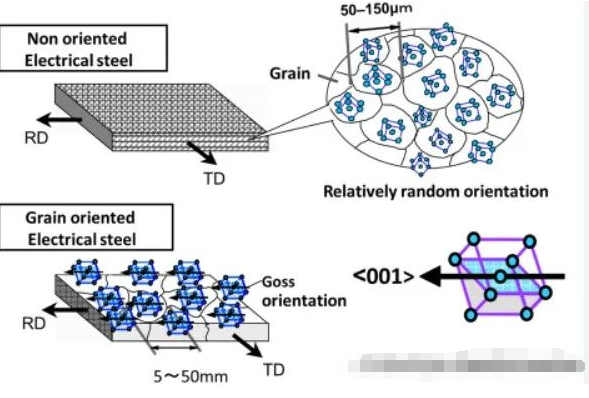

Jidka qulqulka birlabta ee mashiinka qulqulka birlabta ee axial waa hal-cabbir, sidaa darteed birta korontada ee ku saleysan hadhuudhka ayaa loo isticmaali karaa. Birtani waxay sahlaysaa qulqulka inuu dhex maro, taasoo hagaajinaysa hufnaanta.

Matoorada qulqulka radial-ka ayaa dhaqan ahaan isticmaala dabaylo kala qaybsan, iyadoo ilaa kala bar darafyada duubista aysan shaqeynayn. Dabaysha gariiradda waxay keeni doontaa miisaan dheeraad ah, kharash, iska caabin koronto, iyo kuleyl badan oo lumaya, taasoo ku qasbeysa naqshadeeyayaasha inay horumariyaan naqshadda duubista.

Dhammaadka gariiraddamatoorada qulqulka axialaad bay u yar yihiin, naqshadaha qaarna waxay isticmaalaan dabaylo xooggan ama qaybo ah, kuwaas oo si buuxda waxtar u leh. Mashiinnada radial-ka stator-ka ee kala qaybsan, dillaaca wadada qulqulka birlabta ee stator-ka waxay keeni kartaa khasaare dheeraad ah, laakiin matoorada qulqulka axial-ka, tani dhibaato maaha. Naqshadaynta dabaylaha gariiradda ayaa ah furaha lagu kala saaro heerka alaab-qeybiyeyaasha.

3. Horumarin

Matoorada qulqulka axial waxay la kulmaan caqabado halis ah oo ku saabsan naqshadeynta iyo wax soo saarka, inkastoo faa'iidooyinkooda tignoolajiyadeed, haddana kharashkoodu aad ayuu uga sarreeyaa kuwa matoorada radial. Dadku waxay si qoto dheer u fahmaan matoorada radial, hababka wax soo saarka iyo qalabka farsamada ayaa sidoo kale si fudud loo heli karaa.

Mid ka mid ah caqabadaha ugu waaweyn ee matoorada qulqulka axial waa in la ilaaliyo farqiga hawada ee u dhexeeya rotor-ka iyo stator-ka, maadaama xoogga birlabku uu aad uga weyn yahay kan matoorada radial-ka, taasoo adkeyneysa in la ilaaliyo farqiga hawada ee isku midka ah. Matoorka qulqulka axial-ka ee laba-rotor-ka ah ayaa sidoo kale leh arrimo kululaynta, maadaama wareegga uu ku yaal gudaha stator-ka iyo inta u dhaxaysa labada saxan ee rotor-ka, taasoo ka dhigaysa kala-baxa kulaylka mid aad u adag.

Matoorada qulqulka axial sidoo kale way adag tahay in la soo saaro sababo badan awgood. Mashiinka laba-rotor-ka ah ee isticmaalaya mashiinka laba-rotor-ka ah oo leh qaab-dhismeedka yokes (tusaale ahaan ka saarista harqoodka birta ee stator-ka laakiin haysashada ilkaha birta) wuxuu ka gudbayaa qaar ka mid ah dhibaatooyinkan isagoon ballaarin dhexroorka matoorka iyo birlabta.

Si kastaba ha ahaatee, ka saarista harqoodku waxay keentaa caqabado cusub, sida sida loo hagaajiyo loona meeleeyo ilkaha shaqsiga ah iyada oo aan lahayn isku xirka harqoodyada farsamada. Qaboojinta sidoo kale waa caqabad weyn.

Sidoo kale way adag tahay in la soo saaro rotor-ka oo la ilaaliyo farqiga hawada, maadaama saxanka rotor-ku uu soo jiito rotor-ka. Faa'iidada ayaa ah in saxannada rotor-ku ay si toos ah ugu xiran yihiin giraan shabaq ah, sidaas darteed xoogagga ayaa is baabi'inaya. Taas macnaheedu waa in qabsashada gudaha aysan u adkaysan karin xoogaggan, shaqadeeduna ay tahay inay stator-ka ku hayso booska dhexe ee u dhexeeya labada saxan ee rotor-ka.

Matoorada rotor-ka hal-geesoodka ah ee laba-istaatiga ah ma wajahaan caqabadaha matoorada wareegsan, laakiin naqshadeynta stator-ka ayaa aad uga adag oo ay adag tahay in la gaaro otomaatiga, kharashyada la xiriirana sidoo kale waa sarreeyaan. Si ka duwan matoor kasta oo dhaqameed oo leh qulqulka radial, hababka wax soo saarka matoorka axial iyo qalabka farsamada ayaa dhawaan soo ifbaxay.

4. Adeegsiga gawaarida korontada ku shaqeeya

Kalsoonidu waa muhiim warshadaha baabuurta, waxayna caddaynaysaa isku halaynta iyo adkaysiga noocyada kala duwanmatoorada qulqulka axialSi loo qanciyo soosaarayaasha in matooradani ay ku habboon yihiin wax soo saarka ballaaran had iyo jeer waxay ahayd caqabad. Tani waxay ku kalliftay bixiyeyaasha matoorada axial inay si gaar ah u sameeyaan barnaamijyo xaqiijin ballaaran, iyadoo alaab-qeybiye kastaa uu muujinayo in isku halaynta matoorkoodu aysan ka duwanayn matoorada socodka radial-ka dhaqameed.

Qaybta kaliya ee duugoobi karta gudahamatoorka qulqulka axialwaa raadadka. Dhererka qulqulka birlabta ee axial waa mid gaaban, booska raadadkana waa mid aad u dhow, badanaa loogu talagalay in si yar loo "cabiro". Nasiib wanaag, matoorka qulqulka axial wuxuu leeyahay cuf rotor yar wuxuuna u adkeysan karaa culayska rotor-ka ee firfircoon ee hooseeya. Sidaa darteed, xoogga dhabta ah ee lagu dabaqo raadadka ayaa aad uga yar kan matoorka qulqulka radial-ka.

Axle elektaroonik ah waa mid ka mid ah codsiyada ugu horreeya ee matoorada axial. Ballaca khafiifka ah wuxuu ku duubi karaa matoorka iyo sanduuqa gear-ka ee axle-ka. Codsiyada isku-dhafka ah, dhererka gaaban ee matoorka ayaa isna soo gaabinaya dhererka guud ee nidaamka gudbinta.

Tallaabada xigta waa in matoorka axial-ka lagu rakibo giraangiraha. Sidan, awoodda waxaa si toos ah looga gudbin karaa matoorka ilaa giraangiraha, taasoo hagaajinaysa hufnaanta matoorka. Sababtoo ah tirtiridda gudbinta, kala duwanaanshaha, iyo shaftyada wadista, kakanaanta nidaamka ayaa sidoo kale la dhimay.

Si kastaba ha ahaatee, waxay u muuqataa in qaab-dhismeedka caadiga ah uusan weli soo muuqan. Soo-saare kasta oo qalab asal ah ayaa baaraya qaab-dhismeedyo gaar ah, maadaama cabbirrada iyo qaababka kala duwan ee matoorrada axial ay beddeli karaan naqshadeynta gawaarida korontada ku shaqeeya. Marka la barbardhigo matoorrada radial-ka, matoorrada axial-ka waxay leeyihiin cufnaan awood sare leh, taasoo la macno ah in matoorrada axial-ka yar yar la isticmaali karo. Tani waxay bixisaa ikhtiyaarro naqshadeed oo cusub oo loogu talagalay goobaha baabuurta, sida meelaynta xirmooyinka baytariyada.

4.1 Qalab kala qaybsan

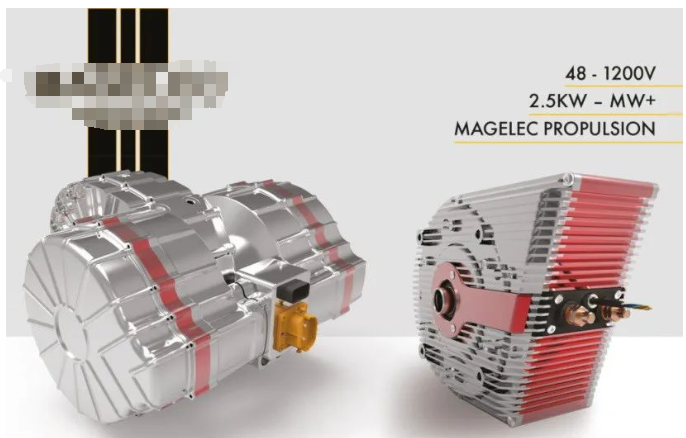

Nidaamka matoorka ee YASA (Yokeless and Segmented Armature) waa tusaale u ah qaabka laba-rotor-ka ee hal-istaare ah, kaas oo yareeya dhibka wax soo saarka isla markaana ku habboon wax soo saarka tirada otomaatiga ah. Matooradani waxay leeyihiin cufnaan awood ah oo ilaa 10 kW/kg ah xawaare u dhexeeya 2000 ilaa 9000 rpm.

Iyada oo la adeegsanayo koontaroole gaar ah, waxay siin kartaa matoorka koronto 200 kVA ah. Koontarooluhu wuxuu leeyahay mug qiyaastii 5 litir ah wuxuuna culeyskiisu yahay 5.8 kiilogaraam, oo ay ku jiraan maaraynta kulaylka oo leh qaboojinta saliidda dielectric, oo ku habboon matoorada qulqulka axial iyo sidoo kale matoorada qulqulka induction iyo radial flux.

Tani waxay u oggolaanaysaa soosaarayaasha qalabka asalka ah ee baabuurta korontada ku shaqeeya iyo horumariyayaasha heerka koowaad inay si dabacsan u doortaan matoorka ku habboon iyadoo lagu saleynayo codsiga iyo booska la heli karo. Cabbirka iyo miisaanka yar ayaa ka dhigaya gaariga mid fudud oo leh baytari badan, taasoo kordhinaysa kor u kaca tirada.

5. Isticmaalka mootooyinka korontada ku shaqeeya

Mootooyinka korontada ku shaqeeya iyo ATV-yada, shirkado qaar ayaa sameeyay matoorro AC axial flux ah. Naqshadda caadiga ah ee loo isticmaalo noocan ah gaariga waa naqshadaha DC axial flux ku salaysan burushka, halka badeecada cusub ay tahay naqshad AC ah oo si buuxda u shaabadaysan oo burush la'aan ah.

Gariiradaha labada matoor ee DC iyo AC way taagan yihiin, laakiin wareegayaasha laba-geesoodka ah waxay isticmaalaan birlabyo joogto ah halkii ay ka isticmaali lahaayeen armatures wareegaya. Faa'iidada habkan ayaa ah inaysan u baahnayn dib-u-rogid farsamo.

Naqshadda axial-ka AC waxay sidoo kale isticmaali kartaa kontaroolayaasha matoorka AC ee saddexda weji ee caadiga ah ee matoorada radial-ka. Tani waxay kaa caawineysaa yareynta kharashyada, maadaama kontarooluhu uu xakameeyo qulqulka wareegga, ee uusan xakameyn xawaaraha. Kontarooluhu wuxuu u baahan yahay soo noqnoqosho 12 kHz ama ka badan, taas oo ah soo noqnoqoshada ugu weyn ee aaladaha noocaas ah.

Soo noqnoqoshada sare waxay ka timaaddaa hoos u dhaca wareegga ee 20 µ H. Soo noqnoqoshadu waxay xakamayn kartaa qulqulka si loo yareeyo gariirka hadda jira loona hubiyo calaamadda sinusoidal sida ugu macquulsan. Marka laga eego dhinaca firfircoon, tani waa hab fiican oo lagu gaaro xakamaynta matoorka oo siman iyadoo loo oggolaanayo isbeddello degdeg ah oo wareegga ah.

Naqshadani waxay qaadataa wareeg laba lakab ah oo qaybsan, sidaa darteed qulqulka birlabta ayaa ka soo qulqula rotor una gudba rotor kale iyada oo loo marayo stator-ka, iyadoo leh waddo aad u gaaban iyo hufnaan sare.

Furaha naqshaddan ayaa ah inay ku shaqayn karto danab ugu badan oo ah 60 V mana ku habboona nidaamyada danab sare. Sidaa darteed, waxaa loo isticmaali karaa mootooyinka korontada ku shaqeeya iyo baabuurta afar-taayirlaha ah ee fasalka L7e sida Renault Twizy.

Danabka ugu badan ee 60 V wuxuu u oggolaanayaa matoorka in lagu daro nidaamyada korantada ee 48 V ee caadiga ah wuxuuna fududeeyaa shaqada dayactirka.

Tilmaamaha mootooyinka afar-taayirlaha ah ee L7e ee ku jira Xeerka Qaab-dhismeedka Yurub 2002/24/EC wuxuu dhigayaa in miisaanka gaadiidka loo isticmaalo qaadista alaabta uusan ka badnayn 600 kiilogaraam, marka laga reebo culeyska baytariyada. Gawaaridan waxaa loo oggol yahay inaysan qaadin wax ka badan 200 kiilogaraam oo rakaab ah, aan ka badnayn 1000 kiilogaraam oo xamuul ah, iyo aan ka badnayn 15 kiilogaraam oo awood matoor ah. Habka wareegga ee la qaybiyey wuxuu bixin karaa xoog dhan 75-100 Nm, iyadoo awoodda wax soo saarka ugu sarreysa ay tahay 20-25 kW iyo awood joogto ah oo ah 15 kW.

Caqabadda qulqulka axial-ka waxay ku jirtaa sida dabaysha naxaasta ahi u kala dirto kulaylka, taas oo adag sababtoo ah kulaylku waa inuu dhex maraa rotor-ka. Wareegga qaybsan ayaa ah furaha lagu xallinayo dhibaatadan, maadaama uu leeyahay tiro badan oo godad tiirar ah. Sidan, waxaa jira meel dusha sare ah oo weyn oo u dhaxaysa naxaasta iyo qolofka, kulaylkana waxaa loo wareejin karaa dibadda waxaana lagu sii deyn karaa nidaamka qaboojinta dareeraha caadiga ah.

Tiirar birlab badan ayaa muhiim u ah isticmaalka qaababka hirarka sinusoidal, kuwaas oo gacan ka geysta yareynta harmonics-ka. Harmonics-kan waxaa lagu muujiyaa kuleylinta birlabyada iyo xudunta, halka qaybaha naxaasta ahi aysan qaadi karin kulaylka. Marka kulaylku ku ururo birlabyada iyo xudunta birta, hufnaantu way yaraataa, waana sababta hagaajinta qaabka hirarka iyo wadada kulaylka ay muhiim ugu tahay waxqabadka matoorka.

Naqshadeynta matoorka waxaa loo habeeyay si loo yareeyo kharashyada loona gaaro wax soo saar badan oo otomaatig ah. Giraangiraha guryaha ee dibadda laga soo saaray uma baahna habayn farsamo oo adag waxayna yareyn kartaa kharashyada agabka. Giraangiraha si toos ah ayaa loo dhaawaci karaa waxaana loo isticmaalaa habka isku xidhka inta lagu jiro habka isku xidhka si loo ilaaliyo qaabka saxda ah ee isu-imaatinka.

Qodobka ugu muhiimsan ayaa ah in gariiraddu ay ka samaysan tahay silig caadi ah oo ganacsi ahaan la heli karo, halka xudunta birtana lagu dahaadhay birta caadiga ah ee laga sameeyay shelf-ka, taas oo si fudud loogu baahan yahay in loo jaro qaab. Naqshadaha kale ee matoorka waxay u baahan yihiin isticmaalka agab birlab jilicsan oo ku jira dahaarka xudunta, kaas oo laga yaabo inuu qaali noqdo.

Isticmaalka wareegyada kala qaybsan waxay la macno tahay in birta birlabta ah aan loo baahnayn in la kala qaybiyo; Waxay noqon karaan qaabab fudud oo si fudud loo soo saari karo. Yaraynta cabbirka birta birlabta ah iyo hubinta fududaynta wax soo saarkeeda waxay saameyn weyn ku leedahay dhimista kharashyada.

Naqshadeynta matoorkan qulqulka axial-ka ayaa sidoo kale loo habeyn karaa iyadoo loo eegayo shuruudaha macaamiisha. Macaamiishu waxay leeyihiin noocyo gaar ah oo lagu sameeyay naqshad aasaasi ah. Kadibna waxaa lagu sameeyay khadka wax soo saarka tijaabada ah si loo xaqiijiyo wax soo saarka hore, kaas oo lagu soo koobi karo warshado kale.

Habaynta ayaa inta badan sabab u ah waxqabadka gaarigu kuma xirna oo keliya naqshadeynta matoorka qulqulka magnetic-ga ee axial, laakiin sidoo kale tayada qaab-dhismeedka gaariga, baakadda batteriga, iyo BMS.

Waqtiga boostada: Sebteembar-28-2023