Qaab dhismeedka iyo nashqada gaadhi koronto saafi ah wuu ka duwan yahay kan caadiga ah ee matoorka gubashada gudaha ee gaadhiga. Sidoo kale waa injineernimo nidaam adag. Waxay u baahan tahay in ay midayso tignoolajiyada baytariga awoodda, tignoolajiyada wadista baabuurta, tignoolajiyada baabuurta iyo aragtida xakamaynta casriga ah si loo gaadho habka xakamaynta ugu fiican. Qorshaha horumarinta ee sayniska baabuurta korontada iyo tiknoolajiyada, waddanku wuxuu sii wadaa inuu u hoggaansamo qaabka R & D ee "saddex toosan iyo saddex siman", oo sii iftiiminaya cilmi-baarista tignoolajiyada muhiimka ah ee caadiga ah ee "saddex jiif" sida ku cad istiraatijiyadda isbeddelka tignoolajiyada "Dariish koronto oo saafi ah", taas oo ah, cilmi-baarista mashiinka wadista iyo nidaamka xakamaynta, batteriga awoodda iyo nidaamka maaraynta, iyo nidaamka xakamaynta tamarta. Soo-saare kasta oo weyn wuxuu dejiyaa istaraatijiyad horumarineed oo ganacsi oo u gaar ah iyadoo la raacayo istaraatiijiyadda horumarinta qaranka.

Qoraagu wuxuu soo saaraa teknoolojiyadda muhiimka ah ee habka horumarinta tamarta tamarta cusub, isaga oo siinaya aasaaska aragtida iyo tixraaca naqshadeynta, tijaabinta, iyo soosaarka tamarta korontada. Qorshuhu wuxuu u qaybsan yahay saddex cutub si loo falanqeeyo teknoolojiyadda muhiimka ah ee wadista korantada ee tamarta korontada ee baabuurta saafiga ah. Maanta, waxaan marka hore soo bandhigi doonaa mabda'a iyo kala soocida tignoolajiyada wadista korontada.

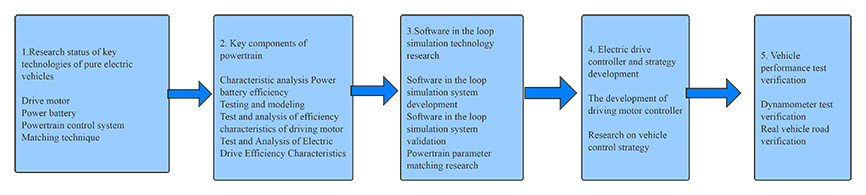

Jaantuska 1 Xidhiidhada Muhiimka ah ee Horumarinta Powertrain

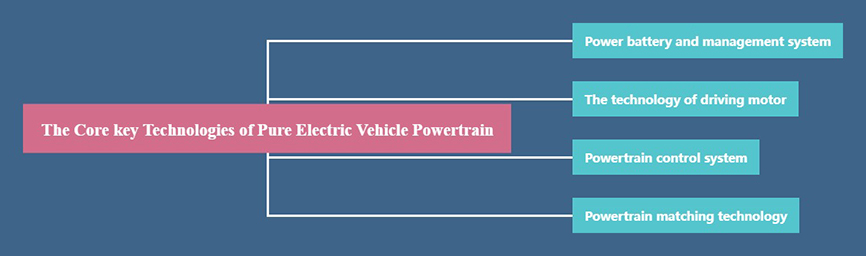

Waqtigan xaadirka ah, teknoolojiyadda muhiimka ah ee tareennada korantada ee baabuurta korantada saafiga ah waxaa ka mid ah afarta qaybood ee soo socda:

Jaantuska 2 Farsamooyinka Muhiimka ah ee Furaha ee Powertrain

Qeexida Nidaamka Matoorka Wadista

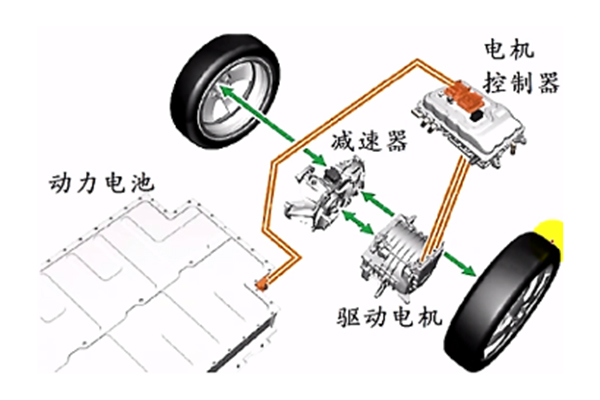

Marka loo eego heerka baytari korantada gaadhiga iyo shuruudaha awooda gaadhiga, waxa ay u bedeshaa wax soo saarka tamarta korantada ee dusha sare ee qalabka tamarta kaydinta tamarta, tamarta waxa loo gudbiyaa taayirrada wadista iyada oo loo marayo qalabka gudbinta, iyo qaybo ka mid ah. Tamarta makaanikada ee baabuurka waxa loo beddelaa tamar koronto oo dib loogu celiyaa agabka kaydinta tamarta marka baabuurku jebiyo. Habka wadista korontada waxaa ka mid ah matoorka, habka gudbinta, kontoroolka mootada iyo qaybo kale. Naqshadeynta xuduudaha farsamada ee nidaamka wadista tamarta korantada inta badan waxaa ka mid ah awoodda, torque, xawaaraha, korantada, saamiga gudbinta ee dhimista, awoodda sahayda korontada, awoodda wax soo saarka, danab, hadda, iwm.

1) Xakamaynta matoorka

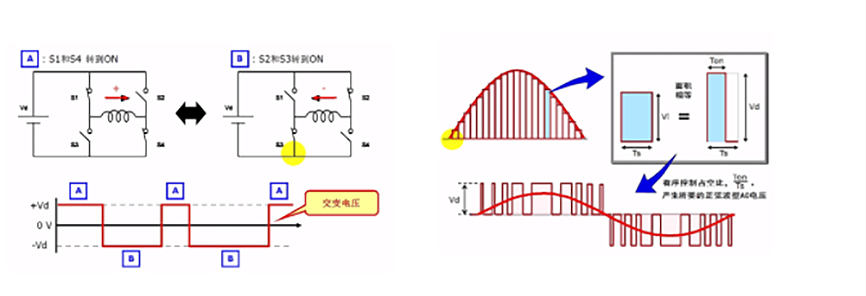

Sidoo kale loo yaqaan inverter, waxay u beddeshaa gelinta tooska ah ee hadda jirta ee batteriga korantada oo u beddeleysa hadda beddelka ah. Qaybaha asaasiga ah:

◎ IGBT: koronto koronto, mabda'a: iyada oo loo marayo kontaroolaha, koontarool gacanta buundada IGBT si loo xiro soo noqnoqoshada iyo isku xigxiga si ay u abuurto isbeddelka hadda jira ee saddex-waji ah. Iyadoo la xakameynayo daminta korontadu si ay u xirto, tamarta beddelka ah waa la beddeli karaa. Markaa danabka AC waxa uu abuuraa iyada oo la xakameynayo wareegga shaqada.

◎ Awoodda filimka: shaqada shaandhaynta; dareemayaasha hadda: ogaanshaha hadda ee dabaysha saddexda weji.

2) Xakamaynta iyo wareegga wadista: guddiga kontoroolka kombiyuutarka, wadista IGBT

Doorka matoorku waa inuu u beddelo DC una beddelo AC, helo calaamad kasta, oo uu soo saaro awoodda u dhiganta iyo qulqulka. Qaybaha asaasiga ah: koronto koronto, capacitor film, dareeraha hadda jira, kontoroolka wadista kontoroolka si loo furo furayaasha kala duwan, u samee qulqulo jihooyin kala duwan, oo dhaliya danab beddel ah. Sidaa darteed, waxaan u qaybin karnaa qulqulka beddelka sinusoidal ee leydi. Meesha leydiyada waxa loo rogaa danab leh dherer isku mid ah. Dhidibka x-xa waxa uu garwaaqsadaa xakamaynta dhererka iyada oo la xakameynayo wareegga waajibaadka, oo ugu dambeyntii ogaanayo beddelka u dhigma ee aagga. Sidan, awoodda DC waxaa lagu xakameyn karaa si loo xiro cududda buundada IGBT ee soo noqnoqoshada iyo isku xigxiga iyada oo loo marayo kontaroolaha si loo dhaliyo awoodda AC ee saddex-waji ah.

Waqtigan xaadirka ah, qaybaha muhiimka ah ee wareegga wadista waxay ku tiirsan yihiin soo dejinta: capacitors, IGBT / MOSFET tuubooyinka beddelka, DSP, chips electronic iyo wareegyada isku dhafan, kuwaas oo si madaxbannaan loo soo saari karo laakiin awood daciif ah: wareegyada gaarka ah, dareemayaasha, xirayaasha, kuwaas oo noqon kara si madaxbanaan loo soo saaro: sahay koronto, diodes, inductors, looxyada wareegyada badan, fiilooyinka dahaaran, radiators.

3) Matoorka: u beddel hadda beddelka saddex-waji oo u beddelo mishiino

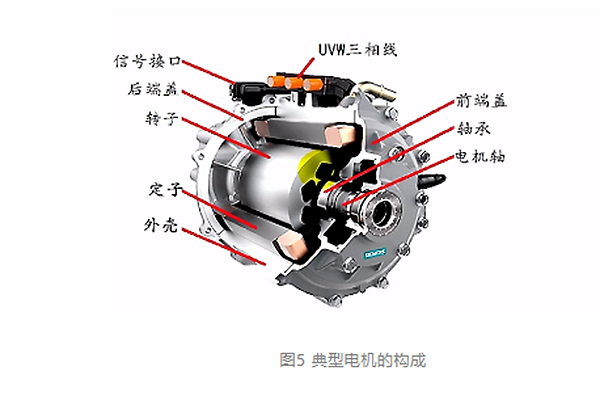

◎ Qaab dhismeedka: daboolka hore iyo kan dambe ee dambe, qolofka, ulaha iyo biraha

◎ Wareegga magnetic: xudunta istator, xudunta rotor

◎ Wareegga: dabeylaha istator, dabeylaha rotor

4) Qalabka Gudbinta

Sanduuqa-gearbox-ka ama wax-yaraha ayaa wax-soo-saarka xawaaraha matoorku u beddelaa xawaaraha iyo wareegga uu u baahan yahay dhammaan baabuurka.

Nooca matoorka wadista

Matoorada wadista waxa loo qaybiyaa afarta qaybood ee soo socota. Waqtigan xaadirka ah, matoorada soo-saarka AC iyo matoorada isku-dhafka magnet-ka joogtada ah ayaa ah noocyada ugu badan ee baabuurta tamarta cusub. Marka waxaan diirada saareynaa tignoolajiyada AC induction motor iyo magnet synchronous magnet joogto ah.

| Matoorka DC | AC Induction Motor | Matoorka Joogtada ah ee Magnet Synchronous | Matoorka Caga-jiid ee Bedeshay | |

| Faa'iidada | Qiimaha Hoose, Shuruudaha Hoose ee Nidaamka Xakamaynta | Kharash yar, Dabool koronto oo ballaadhan, Tignoolajiyada xakamaynta ee la horumariyay, isku halaynta sare | Cufnaanta Awoodda Sare, Waxtarka Sare, cabbir yar | Qaab-dhismeedka Fudud, Shuruudaha Hoose ee Nidaamka Xakamaynta |

| Khasaaro | Shuruudaha dayactirka sarreeya, Xawaaraha hooseeya, qulqulka hooseeya, cimriga gaaban | Aag yar oo hufan Cufnaanta Awoodda Hoose | Qiimaha sare La qabsiga deegaanka oo liita | Isbeddelka qulqulka weyn ee buuqa shaqada |

| Codsiga | Gaadhi koronto oo yar ama yar yar | Gaadiidka Ganacsiga Korontada iyo Baabuurta Rakaabka ah | Gaadiidka Ganacsiga Korontada iyo Baabuurta Rakaabka ah | Gaadhiga awooda isku dhafka ah |

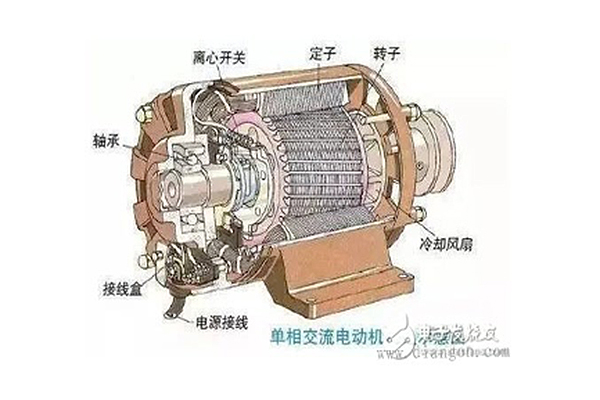

1) AC Induction Asynchronous Motor

1) AC Induction Asynchronous Motor

Mabda'a shaqada ee AC inductive asynchronous motor waa in dabayshu ay dhex mari doonto booska stator-ka iyo rotor-ka: waxaa lagu dhejiyay bir dhuuban oo leh koronto bir ah oo sarreeya. Korontada saddexda weji leh waxay dhex mari doontaa dabaysha. Sida ku cad xeerka Faraday ee induction electromagnetic, waxaa la soo saarayaa goob magnetic wareeg ah, waana sababta keentay in rotorku wareego. Saddexda gariirood ee stator waxay ku xidhan yihiin dhexda 120 darajo, kirishbooyga hadda siddaa wuxuu abuuraa goobo birlab ah oo ku wareegsan. Marka saadka korantada ee saddexda weji ah lagu dabaqo habayntan gaarka ah, meelaha magnetic-ku waxay u beddelmi doonaan jihooyin kala duwan iyada oo isbeddelka hadda beddelka ah ee wakhti go'an ah, abuuraya goob birlab ah oo leh lebis wareeg ah oo xooggan. Xawaaraha wareega ee goobta magnetic waxaa loo yaqaan xawaaraha isku midka ah. Ka soo qaad in kirishbooy xiran la geliyo gudaha, sida uu qabo sharciga Faraday, sababtoo ah magnetic field waa doorsoome, loop-ku wuxuu dareemi doonaa xoogga elektiroonigga ah, kaas oo dhalin doona wareegga wareegga. Xaaladani waxay la mid tahay sida loo sido loop-ka hadda ee goobta magnetic, taasoo dhalinaysa xooga korantada ee loop-ka, Huan Jiangna wuxuu bilaabay inuu wareego. Isticmaalka wax la mid ah qafis dabagaalle ah, wareeg saddex-waji ah oo beddelka ah ayaa soo saari doona goob magnet ah oo wareegeysa iyada oo loo marayo stator, iyo hadda waxaa lagu soo jiidan doonaa baarka qafiska ee gaaban ee giraanta dhamaadka, markaa rotorku wuxuu bilaabaa inuu wareego, taas oo ah sababta matoorka loogu yeero matoor induction ah. Iyada oo la kaashanayo induction electromagnetic halkii si toos ah loogu xidhi lahaa rotor si ay u kiciyaan koronto, insulating flakes xudunta birta waxaa ka buuxsamay rotor ah, si ay birta size yar ay hubisaa in ugu yar ee khasaaraha hadda.

2) AC matoor isku mid ah

Rotor-ka matoorka isku midka ah wuu ka duwan yahay kan matoorka asynchronous. Magnet-ka joogtada ah ayaa lagu rakibay rotor-ka, kaas oo loo qaybin karo nooca dusha sare lagu rakibay iyo nooca dhejiska ah. Rotor-ku wuxuu ka samaysan yahay xaashi bir ah oo silikoon ah, magnet-ka joogtada ah ayaa ku dhex jira. Stator-ku waxa kale oo uu ku xidhan yahay isbedbeddelka hadda jira ee kala duwanaanshaha wejiga ah ee 120, kaas oo koontaroolaya cabbirka iyo wejiga mawjadda sinjiga beddelka hadda, sidaa darteed goobta magnetic-ka ee uu soo saaro stator-ku waa ka soo horjeeda tan rotor-ka, iyo magnetic-ka beertu waa meerto. Sidan oo kale, stator-ka waxaa soo jiitay birlab wuxuuna ku wareegayaa rotor-ka. Wareega wareegga kadib waxaa abuura stator iyo nuugista rotor.

Gabagabo: Matoorka baabuurta korantada ayaa asal ahaan noqday kuwa caadiga ah, laakiin maaha mid kali ah ee waa kala duwan yahay. Nidaam kasta oo wadista matoorku wuxuu leeyahay tusmayn dhamaystiran oo u gaar ah. Nidaam kastaa waxaa lagu dabaqaa wadista baabuurta korontada ee jirta. Intooda badan waa matoorrada is-daba-joogga ah iyo matoorada isku-dhafka ah ee magnet-ka joogtada ah, halka qaarkood ay isku dayaan inay beddelaan matoorada aan doonayn. Waxaa mudan in la tilmaamo in wadista mootada ay isku xirto tignoolajiyada korantada elektiroonigga ah, tignoolajiyada microelectronics, tignoolajiyada dhijitaalka ah, tignoolajiyada kontoroolka tooska ah, sayniska maadada iyo culuumta kale si ay u muujiso codsi dhamaystiran iyo rajada horumarinta ee qaybo badan. Waa tartame xooggan oo ku jira matoorada baabuurta korontada. Si aad u qabsato meel ka mid ah baabuurta mustaqbalka ee korontada, dhammaan noocyada kala duwan ee matoorrada waxay u baahan yihiin ma aha oo kaliya in la hagaajiyo qaab dhismeedka mashiinka, laakiin sidoo kale si joogto ah u sahamiyaan dhinacyada caqliga iyo dhijitaalka ah ee nidaamka xakamaynta.

Waqtiga boostada: Jan-30-2023